Many organizations succeed in piloting an automation project—only to struggle when it’s time to roll it out across additional sites or production lines. Each environment has its own nuances, from lighting and line speed to software integrations and operator workflows. Without a standardized process, what worked in one location quickly becomes a custom rebuild somewhere else.

That’s why scalability isn’t just about technology—it’s about methodology.

The Challenge: Complexity Without Consistency

Automation projects often begin with a single use case: a barcode validation station, a label verification step, or a pallet scanning tower. The first system works beautifully. But when teams attempt to replicate it across ten facilities, inconsistencies appear—different lighting setups, different lens types, and no unified configuration files. Engineering hours multiply, costs rise, and ROI diminishes.

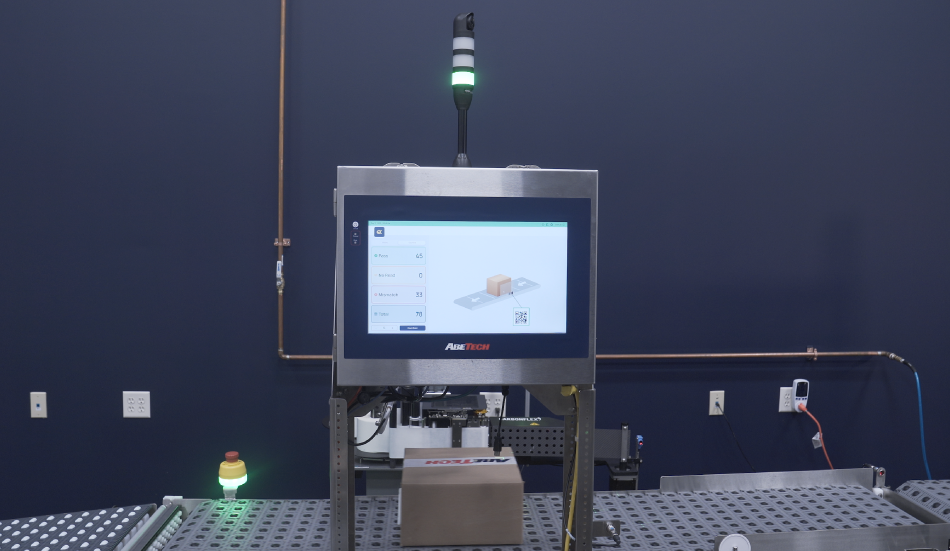

AbeTech solves this through standardization.

The AbeTech Framework for Scalable Automation

AbeTech’s engineers follow a disciplined four-step process designed to eliminate variability and ensure every implementation performs predictably:

1. Understand the Problem

Before a single camera is mounted, AbeTech works directly with clients to define the success criteria. What constitutes a “good” part or a “bad” read? What data needs to be captured and passed upstream? This mutual understanding ensures that every design decision aligns with the operational outcome the client values most.

2. Capture the Right Image

Even the smartest vision system fails without a clean image. AbeTech’s engineering team designs lighting, lensing, and mounting configurations to achieve optimal contrast and clarity, regardless of environment. This ensures that data capture remains reliable even in high-speed or low-light scenarios common in logistics and manufacturing.

3. Apply the Right Tools

AbeTech combines Cognex’s industry-leading rule-based vision tools with AI-driven algorithms to achieve the best of both worlds—speed and intelligence. Traditional tools handle predictable tasks, while AI manages variation. By standardizing how these tools are applied, AbeTech ensures repeatable results across every deployment.

4. Automate and Simplify

Finally, AbeTech builds usability into every solution. From operator interfaces to system reporting, the goal is simplicity. If an automation system is too complicated to maintain, it won’t scale. AbeTech customizes each deployment so that local teams can manage, update, and replicate the solution independently—reducing long-term support costs and accelerating adoption.

Why Standardization Matters for Enterprise ROI

For enterprise clients managing multi-site operations, standardization ensures:

-

Predictable performance across all facilities

-

Faster rollout of new technology or processes

-

Reduced engineering hours during implementation

-

Lower total cost of ownership due to repeatable configuration

-

Simpler support and training through common tools and documentation

It’s not just about getting one project right—it’s about getting every project right.

The AbeTech Advantage

AbeTech’s strength lies in making complexity simple. Our standardization philosophy combines years of integration experience with deep partnerships from industry leaders like Cognex. By aligning people, process, and technology, AbeTech empowers enterprises to deploy automation confidently and scale it without disruption.

Whether you’re building your first machine vision application or expanding a proven system across multiple distribution centers, standardization turns automation from a one-time win into a continuous competitive advantage.

Schedule a consultation to optimize your scanning and vision systems today.