-

Solutions

-

GateKeeper Automated Scanning

GateKeeper Automated Scanning

Check out our full GateKeeper family:

Seamless, smart, and scalable— let us guide you to operational excellence.

-

Stop Motion Scale

Stop Motion Scale

Cut product giveaway at the source with compact, high-precision case weighing and automated rejection in just 36 inches of line space.

Seamless, smart, and scalable— let us guide you to operational excellence.

-

Industrial Automation

Industrial Automation

Data collection and labeling systems for the modern manufacturing workforce.

Seamless, smart, and scalable— let us guide you to operational excellence.

-

Device Management

Device Management

Abe360 is a device lifecycle management platform that simplifies and streamlines the support of your endpoint device environment.

Seamless, smart, and scalable— let us guide you to operational excellence.

-

Barcode Scanning

Barcode Scanning

General purpose, ultra-rugged, DPM, fixed-position industrial, and companion scanners that simplify your warehouse, manufacturing, and production line workflows.

Seamless, smart, and scalable— let us guide you to operational excellence.

-

Mobility Solutions

Mobility Solutions

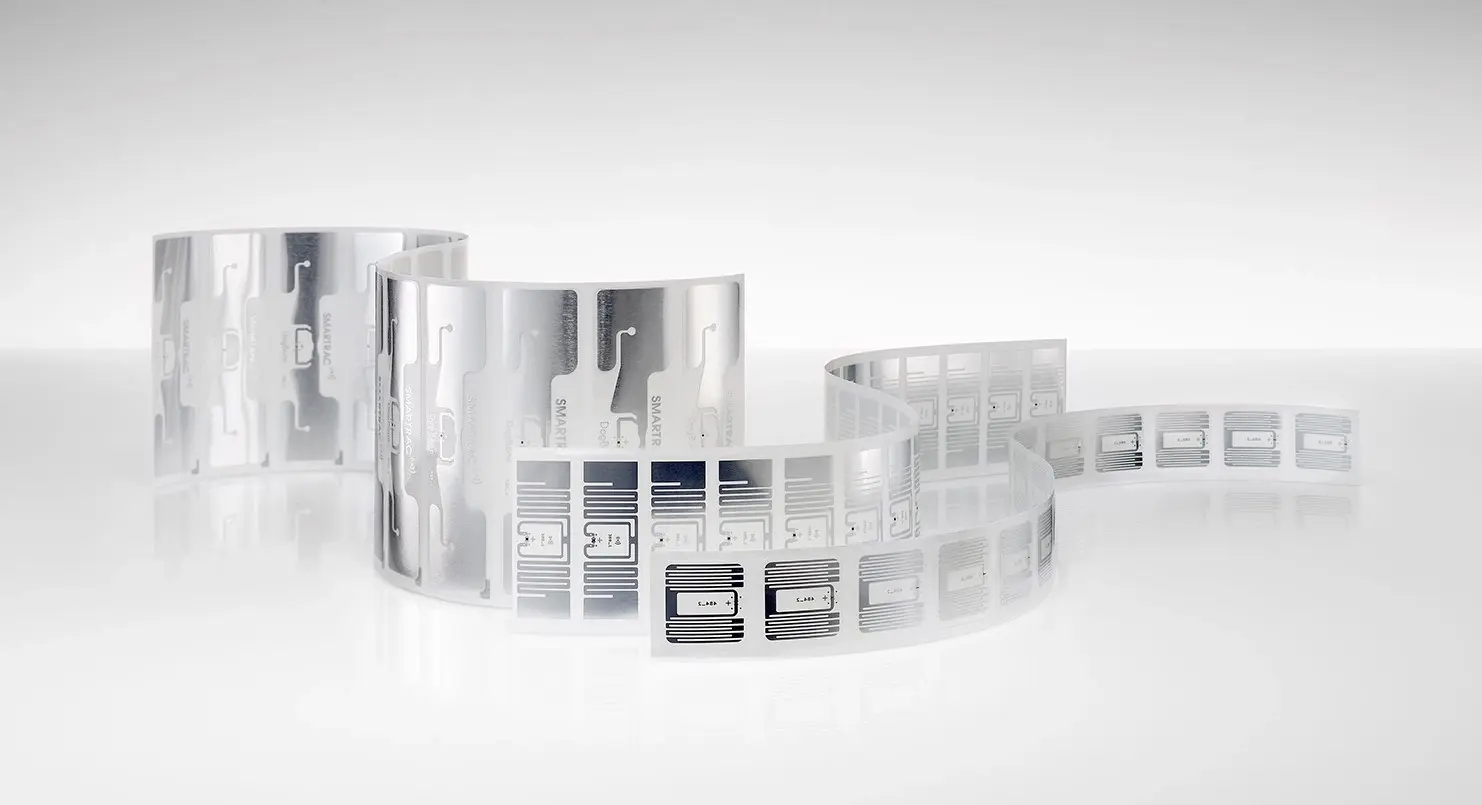

Handheld, vehicle mount, wearable, RFID, tablets, and mobile computers that simplify your warehouse, manufacturing, and production line workflows.

Seamless, smart, and scalable— let us guide you to operational excellence.

Seamless, smart, and scalable— let us guide you to operational excellence.

-

-

Products

Products

Explore the hardware and technologies along with the supplies and consumables you need to increase productivity and efficiency.

-

Hardware / Technologies

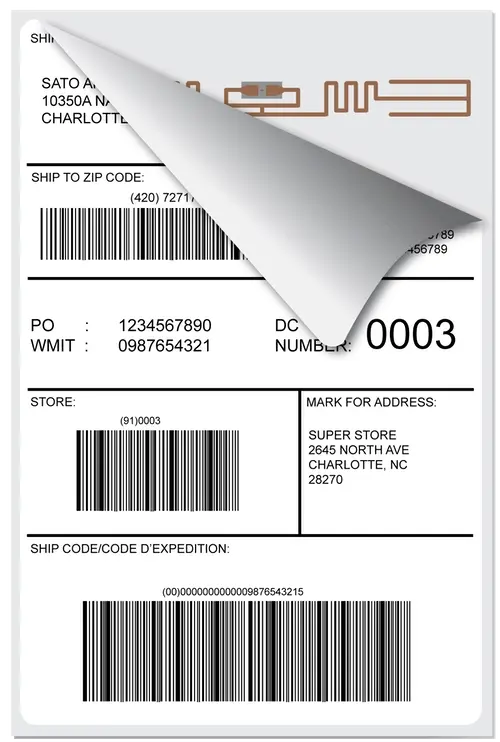

Hardware and technology solutions to equip and prepare your workers for all use cases—from handhelds and vehicle-mounted computers to RFID and automated labeling with verification. -

Supplies / Consumables

Printing supplies and consumables for demanding applications ensure high print quality, durability and read performance, as well as reduced printer wear and tear.

-

-

Services

Services

Exceptional service from mobile computing and automation experts who understand your unique challenges.

-

Managed Services

Control all aspects of business-critical mobility with our simplified endpoint management platform. -

Repair Services

Comprehensive repair plans that meet your budget and service level needs. -

Wireless Networking

Ensure your network infrastructure can support the latest wireless technology and connected workflows. -

Application Services

Optimize your workflows while creating intuitive, efficient applications. -

Warehouse Signage

Streamline aisle identification and rack labeling optimizing processes with a total warehouse labeling solution. -

Wireless Site Surveys

Quickly identify connectivity issues and get your network back up and running quickly.

-

-

Industries

Industries

Industry-specific connected solutions that enable you to meet critical business goals faster with less risk.

-

Manufacturing

Intelligent, agile manufacturing solutions for the enterprise. -

Warehouse & Distribution

Enhance your warehouse and distribution workflows to create an agile, lean, and scalable supply chain. -

Food & Beverage

Improve supply chain visibility, efficiency, and accuracy from packaging to distribution. -

Transportation & Logistics

Unprecedented visibility into your supply chain so you can always deliver.

-

-

Partners

Partners

Strategic partnerships with technology companies on the cutting edge of technological innovation.

-

Zebra

When you need best-in-class enterprise-grade mobility solutions, look no further than Zebra. -

Honeywell

Honeywell's connected technology solutions are transforming the way the world works. -

SOTI

SOTI creates end-to-end enterprise mobility management solutions for the enterprise. -

Cognex

Cognex vision helps companies improve product quality, eliminate production errors, lower manufacturing costs, and exceed consumer expectations.

-

-

Knowledge Center

Knowledge Center

Blog posts, case studies, ebooks, and more from industry thought leaders to guide you as your connected enterprise grows.

-

Case Studies

A growing collection of case studies on use cases for manufacturing, warehousing, and logistics enterprises. -

Blog Posts

Thought leadership for connected technology companies on the cutting-edge. -

Forms

Online forms, printable PDFs, questionaires, and surveys. -

Resources

Browse brochures, spec sheets, and infographics that simplify solution evaluation and support informed decision-making.

-

-

About Us

About Us

Work with a team dedicated to helping businesses simplify their connected technology transformation.

-

Careers

We’re building a team of passionate individuals who inspire others through service and innovation. -

News

The latest industry information and updates on AbeTech's company objectives. -

Giving Philosophy

We’re committed to making a lasting impact through charitable contributions and community-driven efforts.

-