It only takes one unreadable label to bring a high-speed operation to a halt.

Maybe it’s a barcode that won’t scan at the dock door.

Maybe a label peels off in transit.

Maybe a critical printer goes offline—again.

In busy distribution centers, repair depots, and complex supply chains, these failures happen far more often than most leaders realize. The symptoms are obvious: missed shipments, failed audits, manual rework, and frustrated teams.

But the root cause is usually the same: labeling infrastructure that wasn’t designed to scale.

The Hidden Bottleneck in High-Volume Operations

Most organizations still treat labeling as a tactical necessity rather than a core operational system. Labels are reordered when inventory runs low. Printers are added as problems arise. Media choices vary by site. Inventory is tracked in spreadsheets or tribal knowledge.

This fragmented approach quietly creates a cascade of issues:

- Barcodes that smudge, fade, or peel during handling

- Misaligned or inconsistent labels due to manual application

- Downtime caused by mismatched printers, drivers, or firmware

- Emergency reorders and inconsistent label availability across locations

The result is a constant state of reaction—fire drills instead of flow.

What’s missing isn’t effort. It’s a unified labeling strategy.

Why Labels Are No Longer “Just Consumables”

As organizations invest in automation, RFID, machine vision, and real-time visibility, labeling failures become more expensive and more visible. A label is no longer just adhesive and ink—it’s a data carrier, a compliance artifact, and a critical link in your supply chain.

Leading enterprises are changing how they approach labeling by treating it as infrastructure, not inventory.

Here’s what that looks like in practice—and how AbeTech helps make it real.

How AbeTech Fixes the Root Causes

Engineered Labels Built for the Environment

Not all labels are created equal. Heat, abrasion, chemicals, moisture, and handling all impact performance. AbeTech helps enterprises select and validate purpose-built label materials designed for durability, print quality, and consistent scan performance.

The result: fewer scan failures, less rework, and labels that perform from print to delivery.

Smarter Inventory Planning for Critical Media

Running out of labels shouldn’t be a surprise. AbeTech helps organizations move beyond reactive purchasing with structured media programs—such as blanket orders, make-and-hold strategies, and scheduled releases.

This ensures critical labels are always available across sites, eliminating emergency orders, inconsistencies, and production delays.

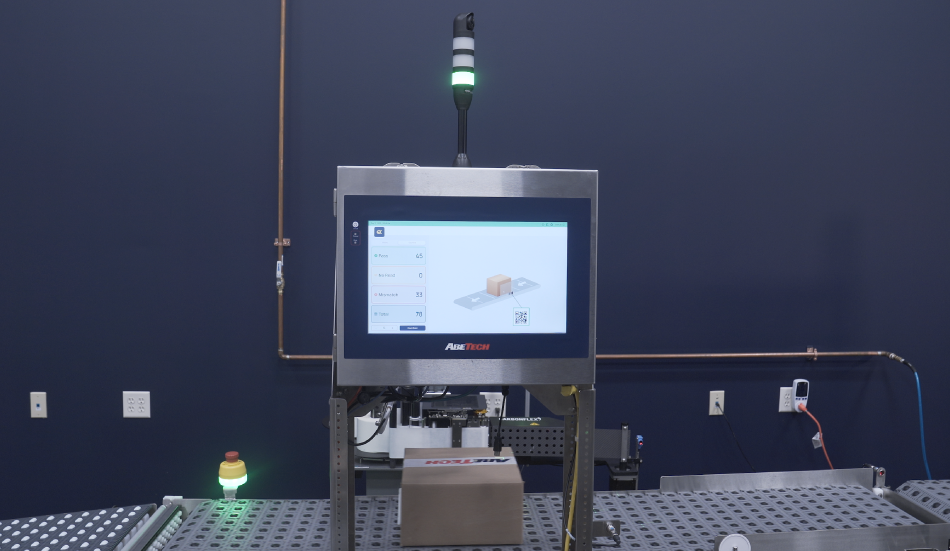

Centralized Print and Device Management

A single aging printer shouldn’t derail an entire operation. AbeTech designs centralized print environments that support:

- Remote configuration and updates

- Firmware and driver standardization

- Health monitoring and proactive maintenance

- Compatibility with secure wireless networks

This reduces IT burden, increases uptime, and keeps operations moving without constant intervention.

Integrated Application and Workflow Design

Labels work best when they’re designed for how work actually happens. AbeTech aligns label formats, encoding, and application methods with real workflows—whether that means pre-kitted labels for field teams, serialized tracking for compliance, or integration with ERP and WMS systems.

The outcome is faster onboarding, fewer errors, and smoother execution across teams.

From Fire Drills to Flow

When labeling and printing are treated as core systems—not last-minute purchases—everything changes:

- Throughput increases

- Error rates drop

- Visibility improves

- Teams spend less time reacting and more time executing

Labeling stops being a weak link and starts supporting the performance of the entire operation.

Rebuild Your Labeling Foundation

If unreadable labels, printer downtime, or media shortages are slowing you down, the issue isn’t just the label—it’s the system behind it.

AbeTech helps enterprises design resilient, scalable labeling programs that grow with operations instead of holding them back.