The pack station is where accuracy matters most. If the wrong product goes into the wrong box, errors ripple downstream—leading to returns, chargebacks, and unhappy customers. Manual checks can’t always keep up with high-volume operations.

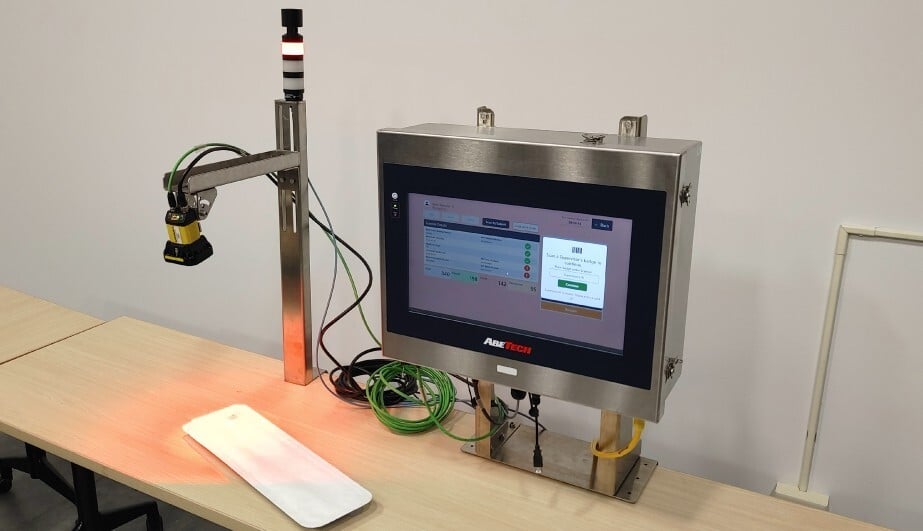

AbeTech’s GateKeeper Pack Station solutions eliminate these risks by automating product verification before packing is complete. Using machine vision and barcode scanning technology, every item is validated against the order, ensuring the right product is packed every time.

Pain Points Solved by Automated Pack Stations

- Packing Errors: Mis-picks or wrong items shipped damage customer trust.

- Manual Slowdowns: Stopping to scan items individually adds labor and time.

- Compliance Gaps: Without verification, shipments risk failing audits or customer SLAs.

- Costly Returns: Incorrect orders increase reverse logistics costs and reduce profitability.

How AbeTech’s GateKeeper Pack Station Helps

- Automated Item Verification: Validates each product before it’s packed.

- Hands-Free Accuracy: Eliminates reliance on manual checks.

- Seamless Integration: Connects with WMS and ERP systems for real-time data capture.

- Scalable Design: Configurable to fit your layout, product mix, and volume needs.

Why It Matters

The pack station is the last chance to get it right. By automating verification at this critical step, enterprises can reduce errors, improve throughput, and deliver with confidence.

With AbeTech, you gain more than technology—you gain a solution engineered to fit your workflows and backed by a team that understands the complexity of enterprise fulfillment.

👉 Schedule a consultation with an automation expert today.