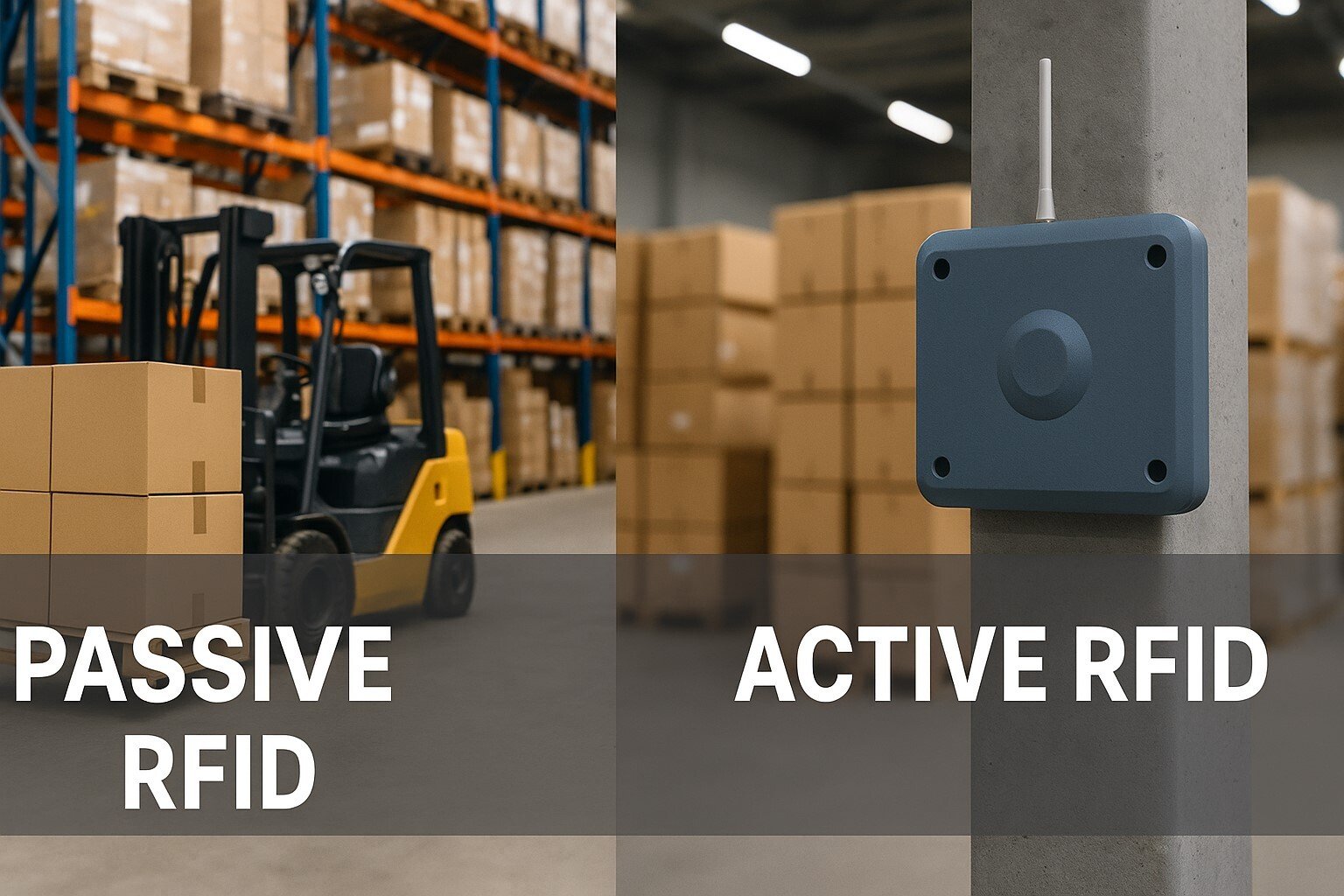

RFID is a powerful tool for gaining visibility into your operations — but not all RFID systems are created equal. One of the most common questions we hear from enterprise clients is: “Should we use passive or active RFID?” The answer depends on your goals, your environment, and how much visibility you really need.

Let’s break it down — with insights from AbeTech’s RFID Practice Lead Adam Hendrickson and Rubin Press of Xemelgo.

What Is Passive RFID?

Passive RFID tags have no internal power source. They only transmit data when energized by a nearby reader.

Key traits:

- Low cost — often under $0.10 per tag

- Point-in-time visibility — reads happen at defined choke points or with handheld scanners

- Limited range — typically 1–30 feet depending on environment and antenna setup

- No battery management required

Best for:

✔ Inventory management

✔ Shipment verification

✔ Cycle counting

✔ Work-in-process tracking (via portals)

✔ Compliance tagging (e.g. Walmart, automotive suppliers)

As Adam noted:

“While clients want real-time locationing, a lot of times point-in-time reads can get them 80–90% of the way — at a fraction of the cost.”

What Is Active RFID?

Active RFID tags have their own power source (a battery), which allows them to broadcast a signal continuously or at intervals.

Key traits:

- High cost — typically $10–$50 per tag

- Real-time locationing — continuous visibility through triangulation

- Greater range — often 100–300+ feet

- Requires battery management

Best for:

✔ High-value asset tracking

✔ Real-time work-in-process visibility

✔ Forklift locationing and task optimization

✔ Equipment tracking in healthcare or aerospace

Rubin summarized it well:“We still see active RFID used in auto and aerospace manufacturing, where knowing exact location in real time is critical to production flow.”

Cost Comparison

|

Feature |

Passive RFID |

Active RFID |

|

Tag Cost |

~$0.10 |

$10–$50 |

|

Read Range |

Up to 30 ft |

100–300+ ft |

|

Infrastructure |

Low to moderate |

High (triangulation + receivers) |

|

Battery |

No |

Yes (maintenance required) |

|

Visibility Type |

Point-in-time |

Real-time |

|

Ideal Use Cases |

Inventory, Shipping |

WIP, Assets, Vehicles |

Choosing the Right Fit

If you're tracking cartons, pallets, or inventory movement through defined points — passive RFID is likely all you need.

If you're tracking high-value tools, vehicles, or want to dynamically assign tasks based on location — active RFID may be worth the investment.

The key is defining your use case before you choose the tech. As Adam noted: “Not every problem is an RFID problem. And not every RFID problem needs active tracking.”

Work With a Trusted Solution Integrator

At AbeTech, we don’t just sell hardware — we help you solve problems. Our team of experts will help you:

- Evaluate your operational needs

- Test the right tag types in your environment

- Design and implement a scalable solution

- Integrate RFID data with your ERP, WMS, or MES

Whether passive, active, or a hybrid approach, we’ll help you get it right the first time.