Keeping important tools and assets properly calibrated is an important part of keeping your operation running smoothly. Whether you use expensive tools and equipment on a manufacturing or assembly line, or you’re keeping tabs on medical device equipment in a lab or hospital, knowing where your assets are located and when they have most recently been calibrated can be difficult with manual procedures.

There are many locationing technologies to choose from, but first you need to understand the specific use case and environment, simplify processes and procedures, and then use technology to enable automation of manual processes where possible.

Understand

Step 1: A “day in the life” of an asset

The first step to asset tracking for tool calibration is to understand your use case by documenting the normal day in the life of your assets. Do tools or equipment change rooms periodically? Do multiple workers interact with these different tools? How is storage location recorded and where do you keep this data? All of these questions will help define the locationing technology and infrastructure that is right for your needs.

Step 2: Asset Tagging and Locationing Infrastructure

Once you have an understanding of the life cycle/use cases of your asset, there are some basic factors to consider:

- What types of tags will you put on your assets?

- What mobile devices, scanners, or physical infrastructure (Fixed gateway readers, antennas, beacons, etc.) will you use to capture location data?

- Where will you store and monitor location data once it is received by your equipment.

Once you have your devices tagged, and chokepoints or wideband readers and antennas set up around your facility, as parts move from work cell to work cell in manufacturing, or from station to station in a lab or clean room facility, the location of each tagged tool or asset can be updated in your database or data warehouse.

Simplify

Step 3: Mobile Sync and Calibration Schedules

Now that you understand your use case and asset tracking requirements, it’s time to consider simplifying your processes even further.

With a digital version of your calibration schedule, you can use a mobile device to pull this data onto a mobile device and use it to build a list of equipment that requires calibration.

Step 4: Asset Locationing

Using a RFID scanner or mobile computer with an RFID sled, you can identify the room the part is located in and use an audible locating application to locate part within the room. This saves time manually looking for devices that need calibration.

Enable

Step 5: Database Integration

Once located the part is flagged as calibrated, this data is synced to your internal database or a cloud server and the operator can move on to next asset.

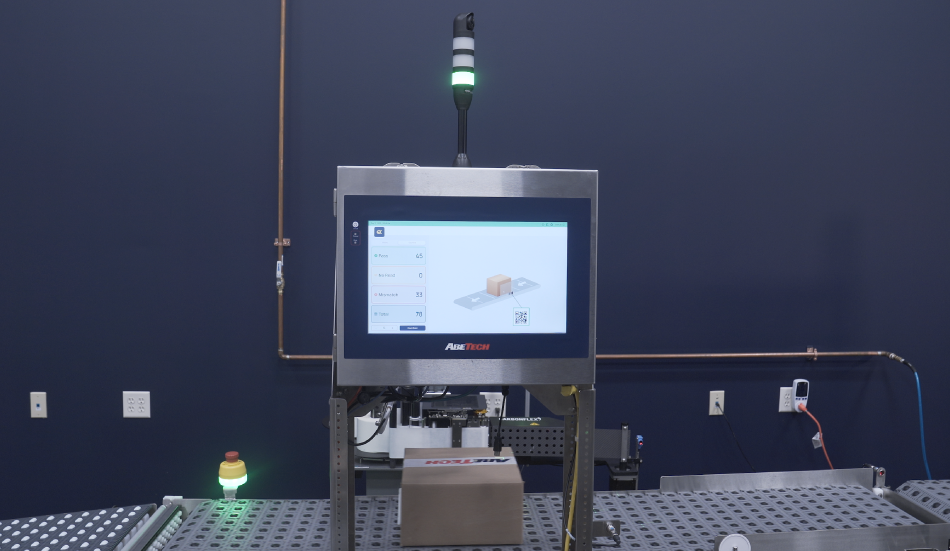

Connect with a solutions expert

Asset tracking and equipment calibration can be complex. Our U|S|E Methodology helps makes the process easy. We can help you take the proper steps to understand your requirements, simplify and automate manual processes, and enable you to find true success and return on your technology investments.

To learn more about RFID for asset tracking or other Intelligent Edge solutions and to get answers to your questions, contact an AbeTech Solution Expert today!