Introduction: The Vision System Dilemma

You invested in a machine vision system to improve quality control and automation. But now, you’re running into problems.

Maybe the system isn’t keeping up with production speeds. Maybe it fails when materials change or struggles with real-time data integration. These are common issues when vision solutions aren’t designed with scalability in mind.

A vision system should not just solve today’s problems—it should be built for growth.

Why Many Vision Systems Fail to Scale

Many businesses install machine vision systems without considering long-term expansion. That’s when problems start appearing:

🔴 Inconsistent Performance Over Time – AI models degrade without retraining and optimization.

🔴 Poor Integration with Other Systems – Vision data needs to sync with ERP, WMS, and automation platforms.

🔴 Limited Flexibility for New Products – Vision systems fail when materials, packaging, or inspection criteria change.

🔴 Not Designed for Multi-Site Rollouts – What works in one facility may not work in another without adaptation.

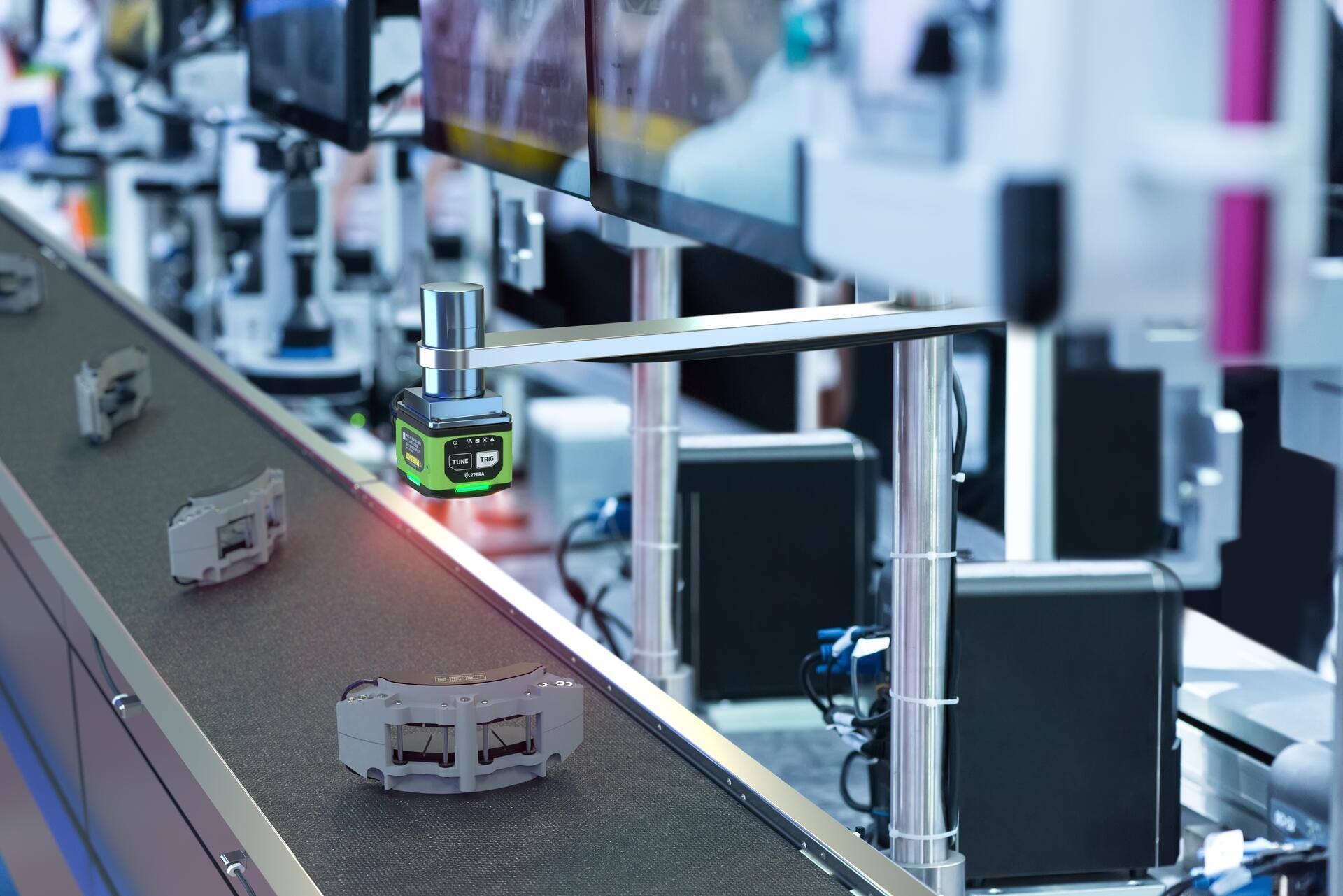

How AbeTech Builds Scalable Vision Systems

At AbeTech, we design machine vision systems for long-term success. Our team of vision engineers, AI specialists, and automation experts ensures your system:

✅ Learns & Adapts Over Time – AI models continuously improve with new data.

✅ Integrates Seamlessly – Vision data connects with your existing enterprise systems.

✅ Handles Material & Production Variability – Advanced algorithms adjust for changes in products, textures, and lighting conditions.

✅ Expands Across Multiple Sites – Standardized frameworks ensure repeatable, high-accuracy deployments.

Real-World Impact: Scaling Vision for Growth

A manufacturer installed an AI-powered defect detection system that worked well initially. But when new materials were introduced, the system started rejecting too many good products.

AbeTech’s team:

🔹 Retrained the AI model with updated sample data to improve accuracy.

🔹 Modified imaging configurations to handle different surface textures.

🔹 Implemented a remote monitoring system to track and adjust model performance over time.

The result? Higher accuracy, lower waste, and a scalable vision system that continues learning.

Why Scalable Vision Systems Matter

Without future-ready vision solutions, businesses face:

❌ Frequent Retrofitting Costs – Vision systems require expensive updates when they aren’t designed for change.

❌ Limited Efficiency Gains – A rigid system means missed automation opportunities as production evolves.

❌ Higher Risk of Failure – Systems that can’t adapt struggle in real-world conditions.

Final Call to Action

If your vision system isn’t keeping up with your business needs, it’s time to rethink your approach. AbeTech’s experts ensure your system adapts, integrates, and scales—without constant rework.