Are manual inventory processes slowing down your operations and driving up labor costs? Many companies struggle with labor-intensive tasks such as manual inventory management, which can lead to bottlenecks, costly errors, and wasted resources. For industries like manufacturing, warehousing, and distribution, these inefficiencies are not only a drain on time but also on profitability. AbeTech, with years of experience in RFID technology integration, stands out as a trusted advisor for enterprises looking to streamline labor and improve inventory management. AbeTech's RFID solutions are tailored to meet the specific needs of each business, ensuring faster, more accurate, and cost-effective operations. By leveraging their deep expertise, AbeTech helps companies automate processes, reduce manual labor, and optimize overall efficiency, positioning them for long-term success.

What is RFID Technology?

At its core, RFID technology consists of three key components: tags, readers, and antennas. These components work together to automatically capture data from RFID tags attached to items or assets, allowing real-time tracking and visibility throughout the supply chain. Unlike barcodes, which require line-of-sight and manual scanning, RFID tags can be read from a distance, even in bulk, without the need for individual handling. This ability to capture data automatically and instantly has a profound impact on labor efficiency and cost reduction.

Reducing Labor Costs with RFID Automation

One of the most immediate benefits RFID brings to organizations is the reduction of labor costs. In traditional inventory management systems, employees are often tasked with manual counting, scanning, and data entry. This process is not only time-consuming but also prone to human error. Every minute spent on manual scanning or correcting errors is a cost to the business, both in terms of time and resources.

With RFID, businesses can automate large portions of the inventory process. Instead of manually scanning each item, employees can use RFID readers to capture data from hundreds or even thousands of tags at once. For instance, a warehouse worker walking through an aisle equipped with an RFID handheld reader can instantly update the inventory system without stopping to scan each pallet or product individually. This automation reduces the need for large teams dedicated to inventory management, allowing businesses to allocate labor to more strategic and value-adding tasks.

Improved Accuracy and Reduced Errors

Manual inventory systems are often plagued by errors that lead to costly consequences such as stock discrepancies, misplaced items, or incorrect shipments. These errors not only slow down operations but can also result in financial losses due to re-shipping, chargebacks, or compliance violations.

RFID technology drastically improves accuracy by providing real-time visibility into inventory levels and locations.  Every item with an RFID tag is automatically tracked as it moves through the supply chain, from receiving to storage, picking, packing, and shipping. This level of accuracy ensures that inventory counts are always up to date, eliminating discrepancies and reducing the need for cycle counts or physical audits. Fewer errors mean less rework and a reduced burden on the labor force.

Every item with an RFID tag is automatically tracked as it moves through the supply chain, from receiving to storage, picking, packing, and shipping. This level of accuracy ensures that inventory counts are always up to date, eliminating discrepancies and reducing the need for cycle counts or physical audits. Fewer errors mean less rework and a reduced burden on the labor force.

Faster Inventory Counts and Real-Time Insights

RFID’s ability to streamline inventory management goes beyond reducing manual labor. It also offers faster inventory counts and real-time insights that are invaluable to business operations. In industries where inventory turnover is rapid or stock levels need to be monitored continuously, RFID provides a level of speed and efficiency that traditional barcode systems simply can’t achieve.

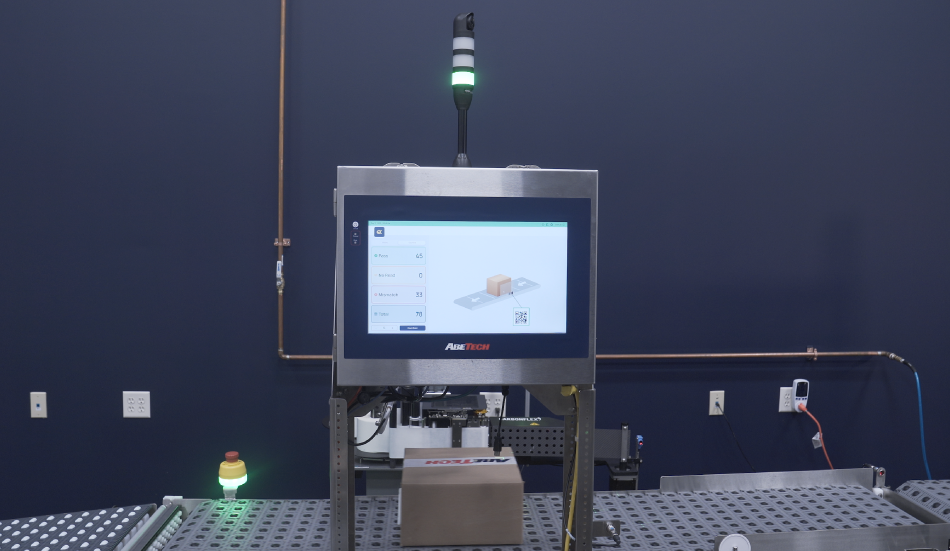

With RFID, businesses can conduct full inventory counts in a fraction of the time it would take with manual processes. For example, what might take a team of workers several days to complete with barcodes can be accomplished in a matter of hours with RFID. AbeTech's RFID Forklift solution is another great way to reduce miscounts, misplaced items, and incorrect stock levels. Additionally, because RFID systems are constantly updating, businesses have access to real-time data that allows them to make informed decisions regarding restocking, demand planning, and order fulfillment.

Optimizing Labor for Strategic Tasks

By automating routine and repetitive tasks like inventory management, RFID frees up employees to focus on more strategic work that adds greater value to the business. Instead of spending hours or days scanning barcodes or counting items, employees can be reassigned to tasks such as process improvement, quality control, or customer service. This shift in focus not only improves employee satisfaction but also drives operational efficiency and business growth.

Moreover, with labor shortages being a growing concern for many industries, RFID helps companies do more with less. Businesses can maintain optimal productivity levels without needing to constantly hire additional labor, providing a long-term solution to workforce challenges.

Scalability and ROI

While the upfront investment in RFID technology may seem daunting for some businesses, the long-term return on investment (ROI) is significant. By reducing labor costs, improving accuracy, and speeding up inventory processes, RFID systems quickly pay for themselves. The scalability of RFID also makes it an ideal solution for companies looking to grow. As operations expand, RFID systems can easily scale to accommodate more assets, locations, and complexity, ensuring that labor costs remain controlled even as the business grows.

Conclusion

RFID technology is revolutionizing how businesses manage their inventory, driving efficiency, reducing labor costs, and minimizing errors. By automating processes that were once manual and labor-intensive, RFID allows businesses to streamline operations, improve accuracy, and redeploy employees to more value-driven tasks. As companies continue to face pressures related to labor shortages and operational efficiency, RFID provides a sustainable and scalable solution that delivers immediate and long-term benefits.

For organizations looking to stay competitive in today’s industrial landscape, investing in RFID is no longer just an option—it’s a necessity. Schedule a consultation with AbeTech RFID experts today!