How to Take a Machine Vision Project from Lab Testing to Full Deployment

🔹 Introduction: Why Many Vision Projects Fail Before Deployment

You’ve identified a need for automated defect detection, quality inspection, or barcode validation. Maybe you’ve tested a machine vision system in a controlled environment, and the results looked promising. But when it’s time to scale up, the system struggles.

✅ False positives skyrocket in real-world conditions.

✅ Production speed is too fast for the system to keep up.

✅ Variability in materials or lighting causes errors.

✅ The system doesn’t integrate smoothly with automation and data workflows.

This is why many machine vision projects stall before full deployment. Moving from a proof of concept (PoC) to a production-ready system requires expert engineering, real-world validation, and a structured deployment process.

🔹 Why Proof of Concept Isn’t Enough

A successful PoC is just the beginning. Many companies assume that once a vision system works in a test environment, it will work in production. But in reality, lab results don’t always translate to factory floors.

Here’s why vision systems often fail after the PoC stage:

🔴 Limited Sample Data – AI models aren’t trained on enough real-world variability.

🔴 Changing Production Conditions – Temperature, humidity, vibrations, and lighting impact performance.

🔴 Integration Challenges – Vision data must sync with ERP, WMS, PLCs, and MES systems.

🔴 Lack of Continuous Optimization – AI models degrade without ongoing fine-tuning.

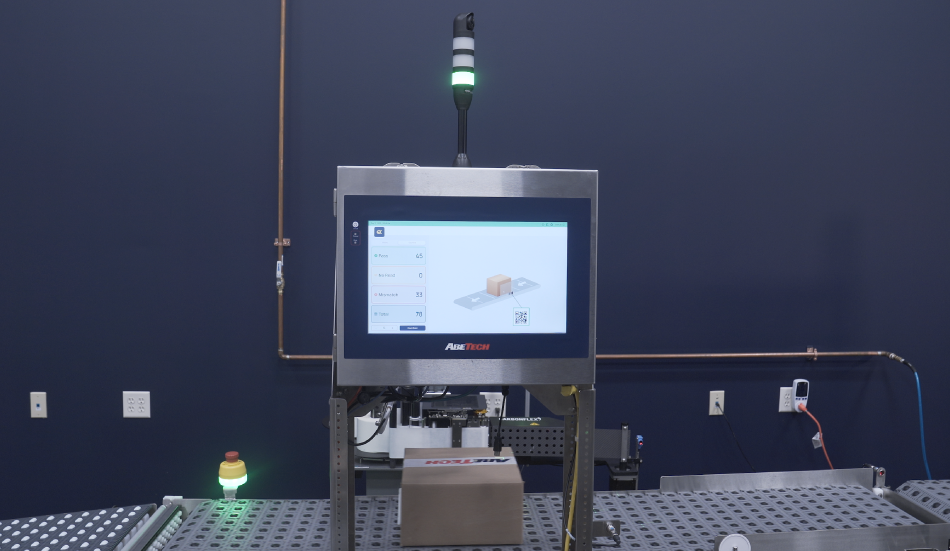

🔹 The AbeTech Approach: From Concept to Reality

At AbeTech, we take a structured, engineering-driven approach to vision system deployment. Our team of vision engineers, software developers, and automation experts ensure that your project:

✅ Works in real production conditions, not just in a lab.

✅ Scales across multiple lines or facilities without rework.

✅ Integrates seamlessly with automation and data workflows.

✅ Continuously improves through AI tuning and system monitoring.

🔹 How We Take Machine Vision Systems from PoC to Full Production

1️⃣ Lab Testing & Proof of Concept

✔ Validate performance in a controlled setting.

✔ Test different cameras, lighting, and deep learning models.

✔ Identify initial limitations before scaling up.

2️⃣ Prototype Development & Real-World Testing

✔ Deploy the system in a live production environment.

✔ Fine-tune settings for materials, surfaces, and environmental conditions.

✔ Measure success against real-world performance benchmarks.

3️⃣ Full-Scale Deployment

✔ Ensure high-speed, high-accuracy operation under production loads.

✔ Optimize data integration with automation platforms.

✔ Minimize downtime and deployment risk.

4️⃣ Ongoing Optimization & Scaling

✔ AI model retraining to reduce false positives and improve accuracy.

✔ Performance monitoring to prevent system degradation.

✔ Scalable framework for multi-site rollouts.

🔹 Real-World Success: Deploying a Scalable Vision System

A manufacturing company successfully tested an AI-driven defect detection system in a lab setting. The system worked—until they moved to production.

❌ False rejects increased due to lighting inconsistencies.

❌ Production speeds were too fast for the original setup.

❌ The AI model struggled with material variation.

AbeTech’s engineers stepped in:

🔹 Recalibrated vision settings for real-world conditions.

🔹 Implemented high-speed image processing optimizations.

🔹 Retrained the AI model with more diverse production data.

🔹 Why a Structured Vision Deployment Process Matters

Vision automation is more than just installing cameras and AI models. Without expert oversight, many projects fail at scale.

✅ Ensures Reliable Performance – Vision systems that adapt to real-world variability.

✅ Reduces False Positives – AI models tuned for your production environment.

✅ Minimizes Risk of Failure – Real-world testing ensures successful full-scale deployment.

✅ Creates a Scalable Automation Roadmap – Designed for multi-line or multi-facility rollouts.

🔹 Final Call to Action

A vision system shouldn’t just work in a lab—it should work in real production. AbeTech’s expert engineers ensure your system is tested, optimized, and ready for scale.